Volkswagen Group’s Bentley Motors has announced a GBP3m investment to double its additive manufacturing (AM) capacity at its factory in Crewe, England where all of its models are assembled.

The existing AM facility has already been applied to a wide range of uses, producing over 15,000 components in 2021 alone.

“This expansion will also enable [us] to utilise advanced technology to create 3D printed vehicle components and even greater personalisation in customer cars,” the automaker said in a statement.

“The investment of this nature in such an innovative process is yet another example of Bentley’s vision to create a long-term, sustainable business model and remain at the forefront of technological progress.”

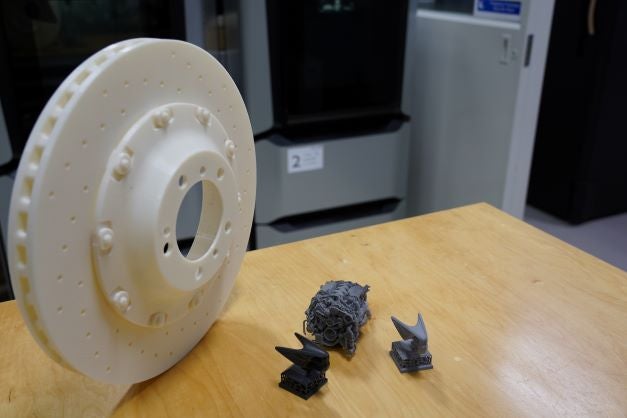

The AM system converts 3D CAD models into physical components and is, the automaker added, “recognised as one of the fastest developing technologies in the world”.

The company has already selected a wide variety of items to print, including on-the-job assisted tools for manufacturing staff, such as lightweight sanding blocks for the wood shop which makes handcrafted interior trim pieces.

Historically accurate tooling equipment needed to make parts for the Bentley Blower Continuation model was created plus face shields provided to the healthcare sector during the COVID-19 pandemic.

AM has been employed to create physical components for several prototype Bentleys, including full-scale powertrain models and aerodynamic wind tunnel models. The advanced techniques have also been used to produce parts for the record-breaking Bentley models that were driven in the demanding Pikes Peak Challenge in America.

“The latest methods help speed up product development, allowing Bentley to produce a profusion of parts without the need to outsource,” the company added. “It is part of the company’s ground-breaking Beyond100 strategy, targeting sustainable mobility leadership by reinventing every aspect of the business.”

The automaker said 3D printing halves parts costs and, by operating around the clock, the facility is capable of producing thousands of components using over 25 different materials.

Workers across the company are now being offered AM training to understand how they could benefit from using the process in their work.

Peter Bosch, Bentley’s manufacturing chief, said: “[Our] approach to additive manufacturing is industry-leading and the facility is quickly becoming a cornerstone of our Dream Factory ambitions. One of the key benefits is that it is efficiency led, cutting down on the cost and complexity of a myriad of jobs.

“This latest investment is also making a significant impact with our colleagues from across the company, helping to create advanced assisted tools to drive continuous improvement throughout manufacturing processes. As we look to the future, there really is huge potential to where this advanced technology can progress, including having a greater ability to personalise parts for our customers and further enhancing the individualisation programme offered on every car.”