SABICPR577b

Previous

SABIC has launched new PP compounds for foam injection moulding (FIM), providing, the supplier claimed, “both light weight and exceptional aesthetics for automotive interiors”.

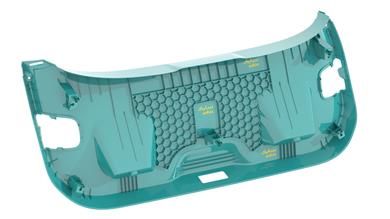

The specialised range of PP compounds come in new mineral-reinforced grades which, the maker said, “can help deliver excellent aesthetics for visible automotive interior parts with complex geometries, such as door panels and trim, seat and trunk cladding, A/B/C/D pillar covers and centre consoles”.

Unlike standard FIM materials, which typically exhibit surface defects, the new compounds have uniformly high surface quality similar to solid injection moulded parts. Compared to solid components, foamed parts made with such PP compounds offer significant weight savings that can help cut emissions. According to a cradle-to-grave life cycle assessment study (pending third-party review), the new materials can help OEMs lower carbon dioxide (CO2) emissions by as much as 15%.

“The automotive industry continues to look for new weight-out strategies that can advance energy efficiency and sustainability goals,” said Abdullah Al-Otaibi, general manager, ETP & market solutions, SABIC.

“Although foam injection moulding produces desirable lightweight parts, manufacturers have been forced to sacrifice aesthetics, until now. We applied our extensive expertise in foaming technology to develop these new compounds to help resolve the issue of surface quality and open new application opportunities for foamed parts.”

Solving the FIM aesthetics challenge

Previously, the FIM process was limited essentially to non-visible parts, restricting its usefulness in automotive applications. Foaming can underperform in surface aesthetics: silver streaking, swirl lines and dimples are common defects. SABIC PP compounds for foamed interior parts are said to deliver low-gloss textured (grained) surfaces with uniformly high quality, including the elimination of streaking and swirling. Talc filler in these grades acts as a nucleator that promotes the generation of finer bubbles which contribute to a consistent surface appearance. For enhanced aesthetics, these grades are currently available in selected automotive interior colours with custom colouring also available.

Optimising weight out benefits

Weight reduction results with these new PP compounds depend on several factors, including the type of FIM technique used. Short-shot moulding, which uses the same tooling as an injection moulded part, can reduce weight by up to 10%. The PPc 9007 variant is formulated for short shot FIM and low impact applications. Core back moulding, which requires part redesign and new tooling, can lower weight by as much as 30%.

Both PPc 9005 and PPc 9015 grades are formulated for core back moulding and deliver medium stiffness and impact.

The choice between the short shot and core back techniques, with their different tooling requirements, also helps to determine whether FIM with PP compounds is cost neutral or delivers cost savings. Additional cost savings are possible from cycle time reductions from flow improvements inherent in FIM.

Another consideration is the foaming process, which can use chemical or physical agents. The new PP compounds are good candidates for use with chemical blowing agents, which are typically preferred for visible foamed parts. These agents are introduced to the moulding machine in the form of a masterbatch, along with the plastic pellets, and activate during the melt phase to release gases for foaming.

Supporting FIM application development and processing

SABIC said it fully supports its new PP compound line with “extensive expertise in foamed part design, development and processing, as well as predictive engineering capability”. The company can provide guidance on the selection of the appropriate chemical blowing agent for each grade and its technical team will collaborate with customers “to achieve excellent aesthetics at the lowest possible part weight”.

To drive future developments in polymer foams, SABIC operates a foam innovation centre in The Netherlands which is equipped with foam process capabilities as well as analytical equipment, and enables the company to develop new foam products and technology innovations and collaborate with customers.

The new compounds have launched in Europe, with availability in the Americas and Asia/Pacific to come.