Renault said over 300 patents had been lodged for the design of the Megane E-Tech Electric.

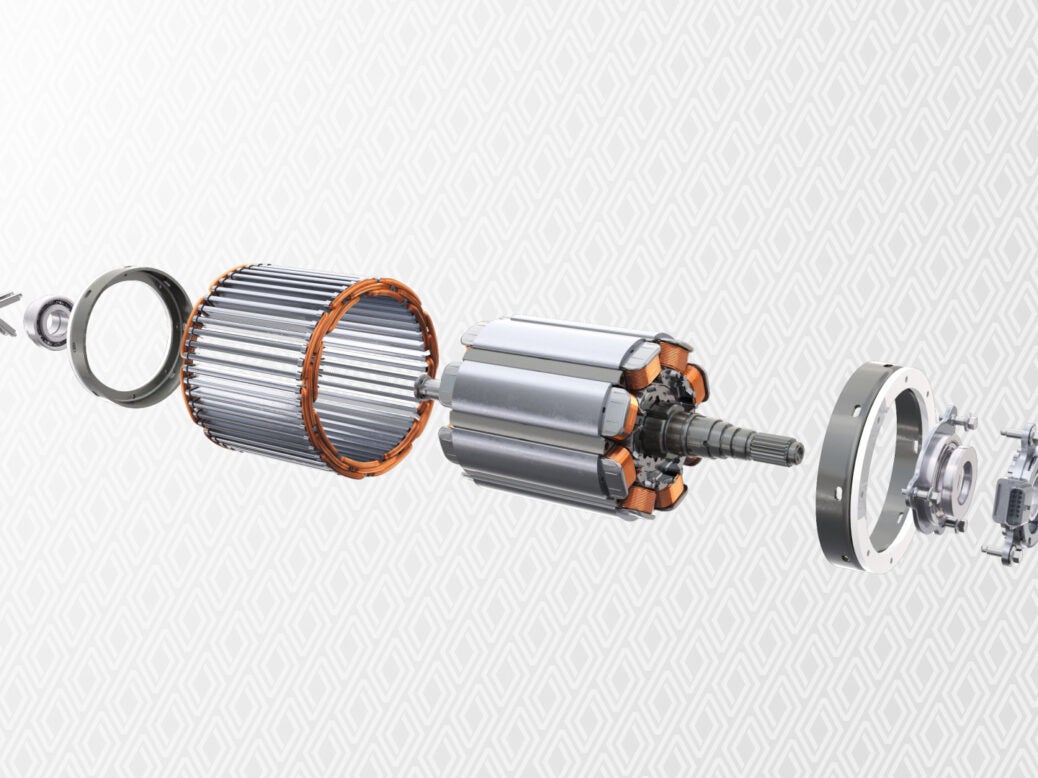

The automaker said it saw sees the electric motor play a strategic role in the EV value chain and has decided to design it entirely in house. Focussed in the greater Paris region, manufacturing and assembly of all the active parts (rotor, stator, power electronics, reducer) are done at the Cleon plant (Seine-Maritime) with fewer materials and energy used in the process, while R&D is concentrated at the Technocentre in Guyancourt (Yvelines).

“We invented a magnet-free rotor winding process. The magnet has been replaced by copper, which has a much smaller impact on the environment. The patented process also makes it possible to modulate the current flowing through the rotor so as to limit how much electricity the battery uses, especially at high speeds and on motorways,” said Edouard Nègre, electrical motor design leader at the powertrain design department.

The new rotor winding process features a number of advantages: it is more environmentally friendly as it is magnet-free, and therefore free of rare-earths; it is robust and reliable with optimised efficiency through limiting electricity use (by modulating current) and therefore reducing energy waste, especially at high speeds or on the motorway; production costs are lower as the technology is used for the engines in the Zoe, Twingo, Kangoo and Master Electric models which are all made on the same production line in Cleon.

A new process

Renault designed and patented a new magnet free, electrically excited, synchronous motor for the E-Tech Electric. The technology makes the engine more efficient while reducing its impact on the environment. It does not use hard to recycle rare earth metals such as neodymium, whose extraction and processing produce toxic waste.

Magnets have been replaced by copper coils for which the order and position of each wire have been studied to withstand the centrifugal force of the rotor.

In addition to the environmental benefits, the rotor winding technology means the new motor performs very well over wide a range of torque and speed. Unlike permanent magnet motors, engineers have been able to use their invention to inject current into the rotor winding and thereby alter the level of magnetic excitation. As such, when the motor is not being heavily used, excitation can be reduced, this in turn uses less magnetic forces and means less energy loss.