Together with startup Volterio, Continental’s development and production service provider Continental Engineering Services (CES) is developing an intelligent charging robot that it says will make filling up with electricity much easier and more convenient in the future.

CES and Volterio have now entered into a partnership that will see the latter develop the first near-production systems for the jointly designed charging robot by mid-2022. CES will then also develop the system to production maturity and ultimately take over the production of the charging robot.

Volume production of the system is planned for 2024 and will take place in Germany.

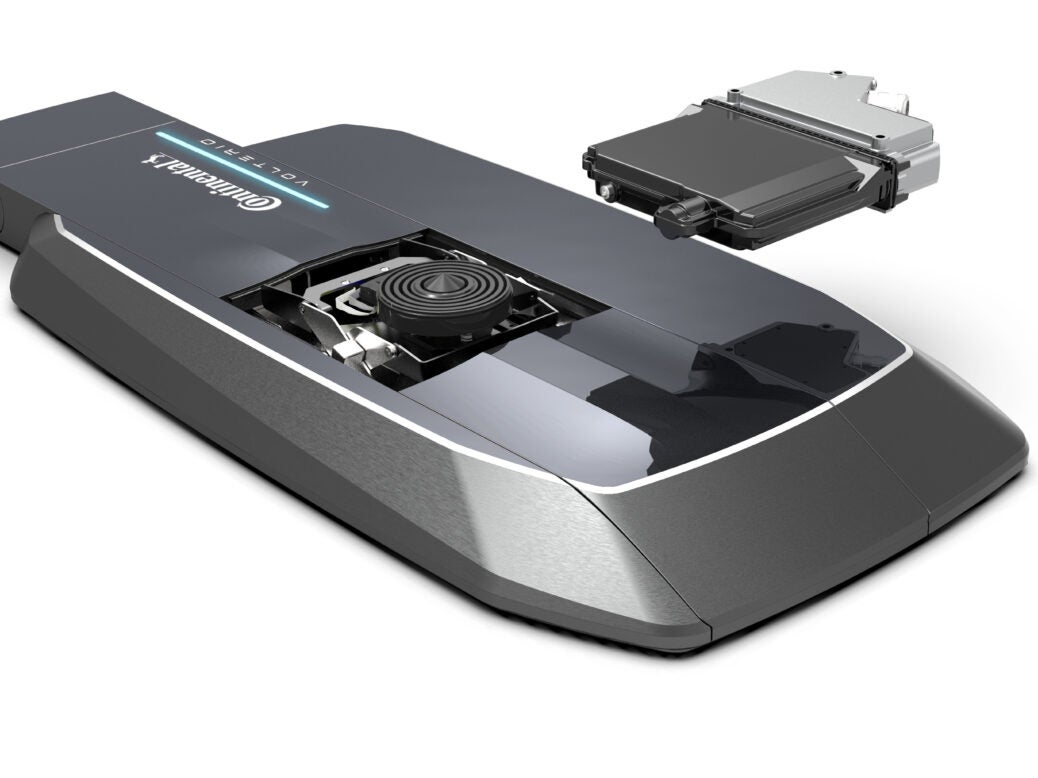

The fully automatic charging solution comprises two components: one unit in the underbody of the vehicle and another on the garage floor. As soon as the car is parked, the two components connect automatically via a smart system, which among other options is controlled via ultra-broadband – a radio-based communication technology for short-range data transmission.

Conti says a practical advantage of this is that the car does not have to be parked accurately. The charging robot corrects for deviation of up to 30 centimeters from the ideal parking position. In addition, it is irrelevant what angle a vehicle is positioned in relation to the floor unit. The conical design of the physical connector between the floor and vehicle unit permits any alignment and orientation between the units.

“Our charging robot is a real step in the evolution of making electric mobility more convenient and suitable for everyday use,” says Dr. Christoph Falk-Gierlinger, managing director of CES. “With Volterio, we have the ideal partner for developing an efficient and simple solution for charging electric vehicles. Through this cooperation, we are combining the creativity and flexibility of a young start-up with the development experience and automotive expertise of Continental Engineering Services.”

Content from our partners

Christian Flechl, managing director at Volteri said: “Continental has the necessary production capacity and scaling capabilities.”

Key advantages of the innovative charging robot

Continental says the the energy flows through a physical connection, just as it does in conventional charging stations. This means that – unlike wireless inductive charging via a magnetic field – hardly any energy is lost when filling up with the charging robot. This makes this solution particularly sustainable and efficient, it is claimed.

In addition, charging is very convenient thanks to the robot technology. Unlike charging stations, users no longer have to worry about any aspect of charging, such as handling heavy, potentially contaminated or rain-soaked charging cables in confined garages. The charging process runs completely automatically. Furthermore, communication between the ground and vehicle units via ultra-broadband ensures that the vehicle and charging robot are aligned prior to charging with centimeter precision – the user can park relatively casually, the technology does not require accurate parking. The system is also straightforward and quick to install. For example, the floor unit can simply be placed on the garage floor or bolted down. The technology already offers what will be essential in the future: if vehicles drive fully automatically and also park themselves in parking garages, automated charging solutions will be part of everyday automotive life.

The charging solution is initially provided for use in private households with a suitable rating of 22 kW alternating current. The solution is a retrofit, so it can be retrofitted in existing model variants of vehicles.

In a second step, a fast-charging solution for public areas that can be retracted into the ground will be developed, for example for parking garages, filling stations or factory areas with a charging capacity of more than 50 kW direct current. This also includes corresponding variants, for example for fleet management of commercial vehicles.