This announcement is seen as a much needed boost to the ailing British car industry.

Tata Group, the owner of Tata Motors and Jaguar Land Rover has announced that it will build an electric vehicle battery factory in the United Kingdom. The group currently manufactures Jaguar and Land Rover branded luxury cars, SUVs in the UK.

- New UK EV Battery plant built for the wider market

- Likely to be based at Somerset UK, to create 9,000 jobs

- Announcement hailed by the British Government

Tata Group UK EV battery plant: a £4 billion plus investment

With an investment of more than £4 billion, Tata Group will establish local battery production with a view to supply to brands it owns like JLR and Tata Motors initially.

The all-new EV battery plant by Tata will have a capacity of 40GWh, higher than the eventual 38GWh targeted for Envision’s battery factory next to Nissan’s plant in Sunderland, UK. The Faraday Institute forecasts that the UK needs a total of 100GWh of local capacity by 2030 to satisfy demand for EV production, rising to 200GWh by 2040.

It was widely reported yesterday (18 July) that Tata had identified a site in Somerset to build a battery factory, with the potential to create some 9000 jobs, and an official announcement was expected imminently.

Confirming the battery plant announcement, Tata Sons chairman N Chandrasekaran said: “Today, I am delighted to announce the Tata Group will be setting up one of Europe’s largest battery cell manufacturing facilities in the UK. Our multi-billion-pound investment will bring state-of-the-art technology to the country, helping to power the automotive sector’s transition to electric mobility, anchored by our own business, JLR. “With this strategic investment, the Tata Group further strengthens its commitment to the UK, alongside our many companies operating here across technology, consumer, hospitality, steel, chemicals, and automotive.”

The firm has yet to officially confirm whether the factory will be sited at Bridgewater in Somerset – a location historically linked with battery factory plans from various automotive manufacturers including Tesla, Rivian and JLR itself.

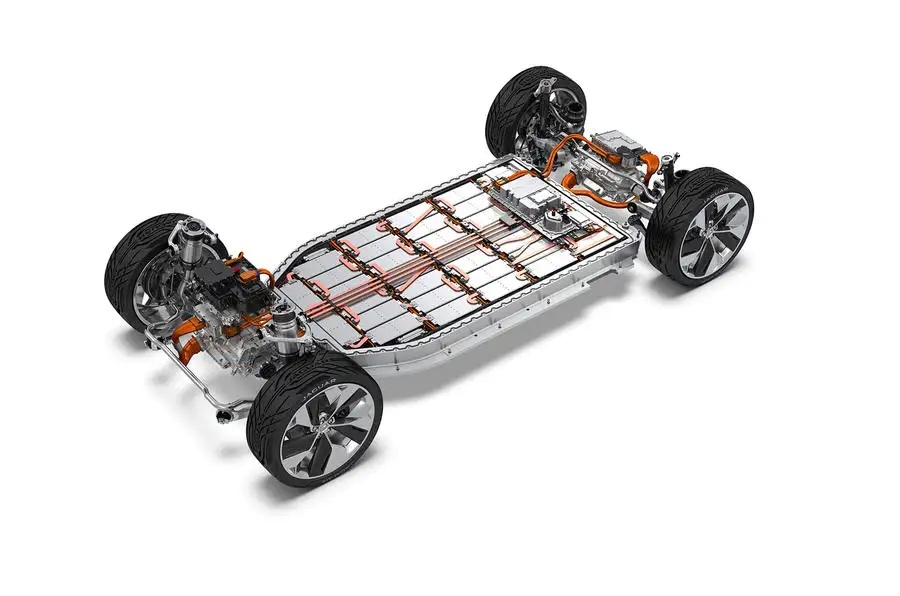

The Tata Group will produce “sustainable battery cells and packs for a variety of applications within the mobility and energy sectors”, following a ‘rapid’ ramp-up phase which will see the plant built and begin operations inside three years.

The Tata Group also plans to “maximise its renewable energy mix” at the battery factory, ultimately targeting 100% ‘clean’ power. A core component of its sustainability ambitions will be the recycling of batteries in house, aiming to create a “truly circular economy ecosystem” by recovering raw materials for re-use in new batteries.

British Prime Minister hails Tata Group’s announcement

Indeed, the British Prime Minister Rishi Sunak hailed Tata’s selection of the UK for its first battery factory outside India as “a huge vote of confidence in Britain.”

“It will not only create thousands of skilled jobs for Britons around the country, but it will also strengthen our lead in the global transition to electric vehicles, helping to grow our economy in clean industries of the future,” he added.

Tata’s UK EV battery plant will be for the wider market

Tata Motors chief financial officer PB Balaji confirmed plans for a European battery plant at Auto Expo 2023 in Delhi, India. It will primarily supply JLR and India-based Tata Motors but will also sell batteries to the wider market. It will produce cells using two chemistries – lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) – with the latter earmarked for JLR, Balaji confirmed. “We are well covered on the production plans for batteries, but we will require some cell capacity coming into Europe,” said Balaji.

Tata’s UK EV battery plant: a step in right direction

The move will be a significant step towards ensuring JLR complies with European ‘rule of origin’ regulations for electric vehicles, which become stricter from 2024 due to Brexit agreements. The new rules will require that 45% of the value of an EV produced should come from the EU or the UK to qualify for trade without tariffs, increasing to 65% in 2027.