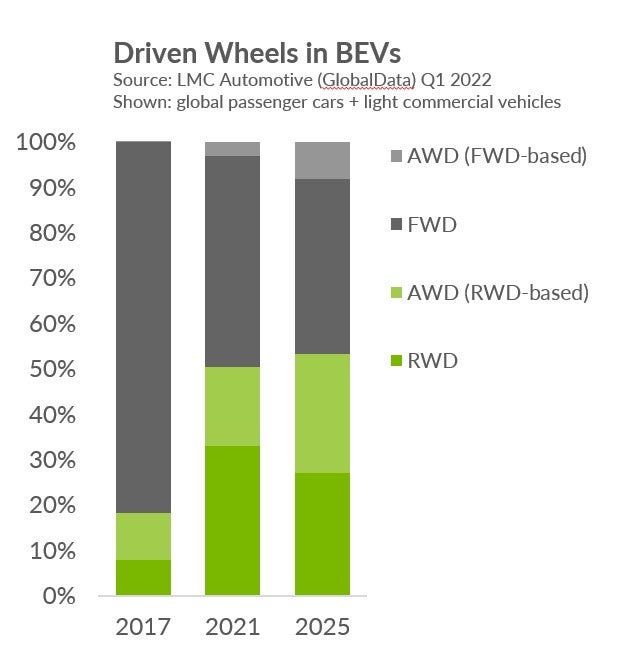

Legacy BEVs have mostly been ICE-conversions and therefore front-wheel-drive. But BEV automakers are starting to adopt rear-wheel-drive. Analysts at GlobalData/LMC have taken a closer look.

The location of the electric drive motor in a battery electric vehicle (BEV) can significantly affect vehicle efficiency, handling, driving experience, packaging, safety, and cost.

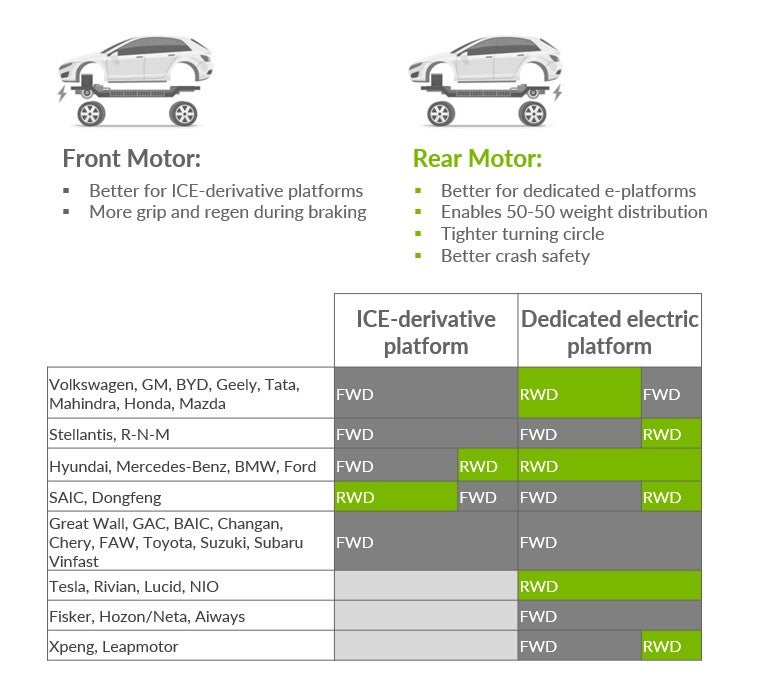

Legacy BEVs have mostly been battery-electric conversions of ICE-powered vehicles and therefore front-wheel-drive (FWD). The electric motor is simply placed where the combustion engine used to be.

This option minimises investment and offers an easily packageable solution with the potential to fit off-the-shelf motors and inverters. Reusing an existing architecture also offers the potential to carry over much of the chassis components including hub, suspension and steering.

On the other hand, a dedicated battery-electric architecture offers multiple benefits: the ability to place the primary driving motor under the rear floor provides more space both in the cabin and under the bonnet. This frees up more space for cooling, control, and climate components, or an additional motor to allow all-wheel-drive (AWD) capability or additional cargo capacity.

As a result of these tangible advantages, automakers have been adopting rear-wheel-drive – some for the first time – particularly in new, dedicated electric platforms.

Front-motor applications have an advantage during regenerative braking: the weight transfer to the front wheels offers a grip benefit and allows higher levels of regen. In rear-motor vehicles, a negative torque to the rear wheels can cause instability, much like applying a handbrake whilst moving, and this places additional requirements on the traction control system.

On the other hand, during acceleration, the weight shifts to the rear and FWD BEVs can experience torque steer, the sensation of the wheel pulling to one side. RWD BEVs avoid this as the hubs are typically fixed centrally.

Other advantages of RWD include 50:50 weight distribution for optimal handling. A single-rear-motor vehicle also removes an uncrushable mass from the front crash stack-up, improving crash safety. It also enables a tighter turning circle, as no drive shafts are required on the front axle.

Ultimately, the ‘best’ solution depends on the application.

As a driving enthusiast, in my opinion, RWD will always be the most fun to drive. But the best of both worlds is an AWD setup, as it makes the best use of both axles by distributing power accordingly.

This dynamic can be increased even further with multiple motors on each axle. This is where some high-performance BEVs are heading, with tri- and quad-motor setups, as they offer torque vectoring for superior cornering and off-road capability. Rivian’s quad-motor system is a good example of this.

Within the ICE and hybrid vehicle sector, RWD is the mainstay of the premium segment, but 65% of global production is FWD or FWD-based. In the BEV segment, the market is converging on a 50-50 split.

Oliver Petschenyk, powertrain analyst, LMC Automotive (a GlobalData company)